- 首頁

- 产品

- 行业

- 关于我们

- 下载

- 技术

- 新闻

-

联系我们

Under the global consensus on carbon neutrality, energy consumption in the industrial sector has become a key challenge for the sustainable development of enterprises. In traditional industrial control systems, tens of thousands of electromagnetic relays act like "energy sponges", with their coils constantly consuming electricity, contact heating losses, and unoptimizable control methods, invisibly devouring huge amounts of electricity bills each year. According to estimates, for a medium-sized manufacturing enterprise, the energy consumption related to relays alone accounts for 3-5% of the total electricity consumption, which represents a significant carbon footprint.

Gordon Electric actively responds to the national "dual carbon" strategy, deeply integrating solid-state relay technology into the green manufacturing system. Through technological innovation, it helps enterprises achieve precise control of energy consumption and system optimization, becoming a key fulcrum for energy conservation and emission reduction in the industrial sector.

The inherent energy-saving genes of the product: reducing energy consumption from the source

The energy-saving features of Gorden solid state relays start from their basic design:

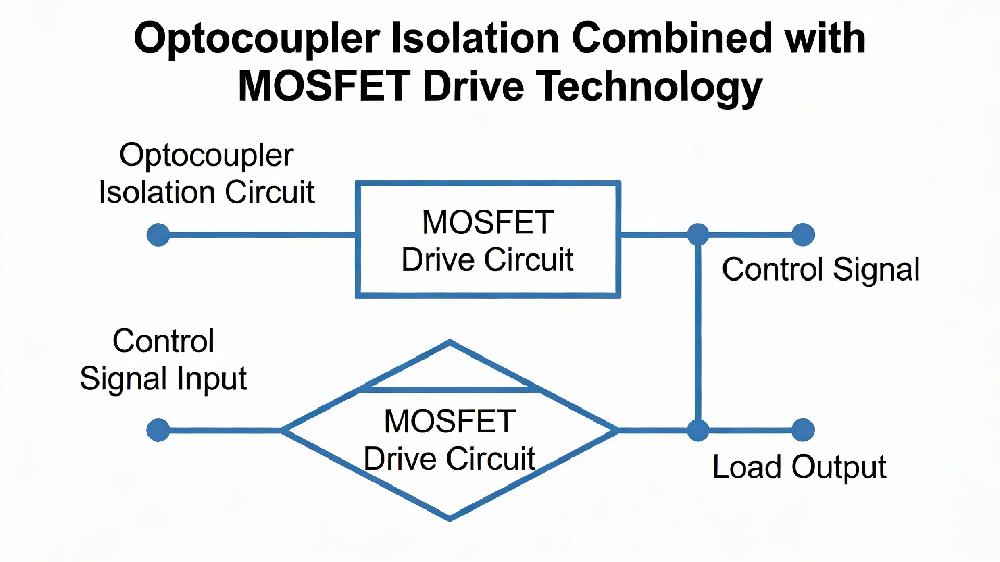

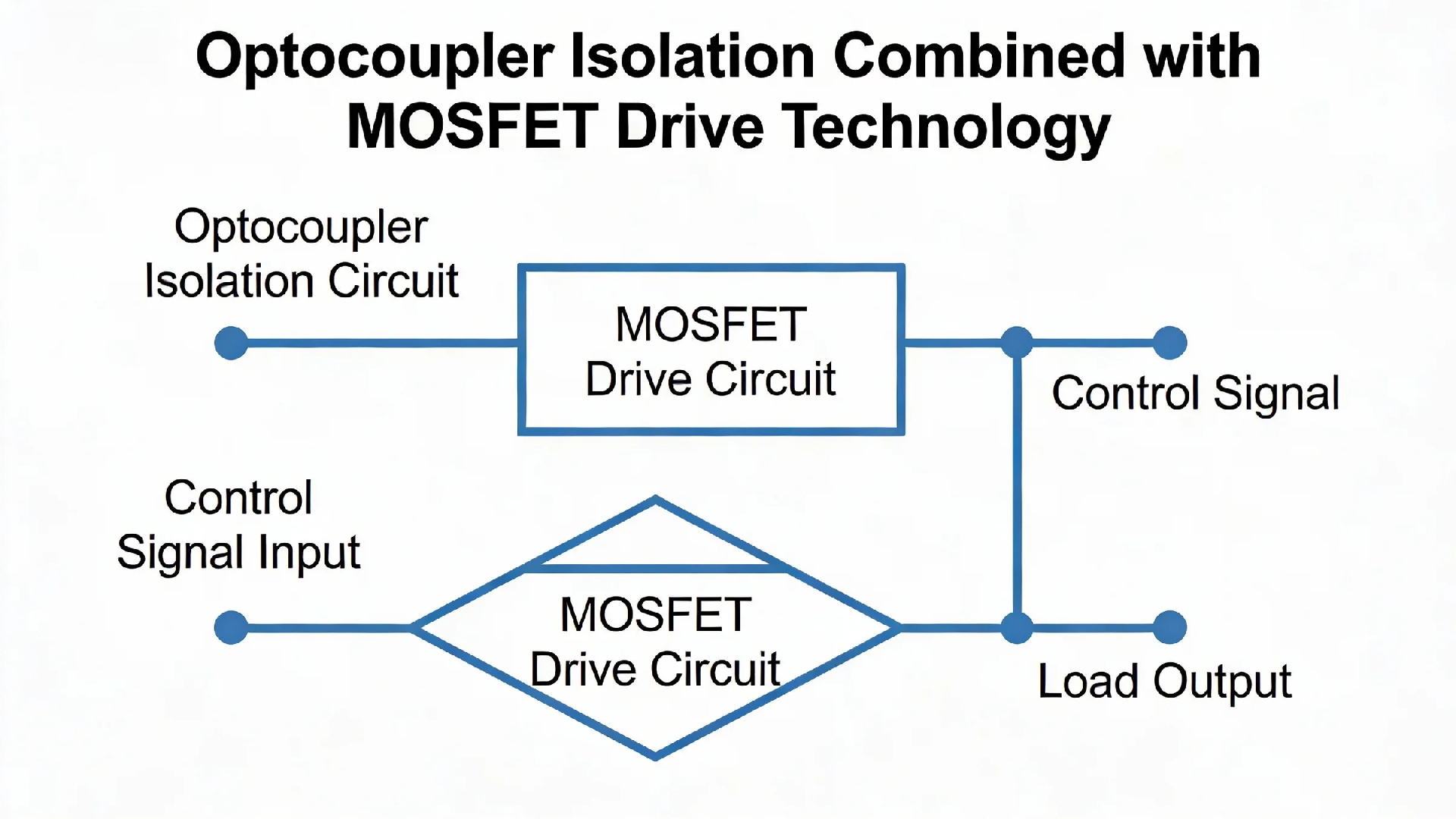

Low-power consumption driving technology: By adopting a technical solution that combines optocoupler isolation and MOSFET driving, the power consumption at the control end is reduced to less than 1/10 of that of traditional electromagnetic relays. The driving power consumption of a single relay is decreased from 1-3W to 0.2-0.5W.

Ultra-low on-resistance drop: Adopting the latest trench-gate MOSFET technology, the on-resistance can be as low as 0.8mΩ. At a rated current of 100A, its own power consumption is reduced by more than 60% compared to traditional products.

Intelligent standby mode: Automatically enters a low-power sleep state during non-working hours, with standby power consumption less than 0.1W.

In a large home appliance manufacturing base in South China, after replacing over 2,000 traditional electromagnetic relays with Godel low-power solid-state relays, the annual electricity saved by the relays alone reached 156,000 kilowatt-hours, equivalent to a reduction of 124 tons of carbon dioxide emissions and a saving of over 100,000 yuan in electricity costs.

Fine control on the load side: Making every kilowatt-hour count

The true potential for energy conservation lies in intelligent control of the load:

Motor control optimization:

Dynamic soft start technology: It adaptively adjusts the start-up curve based on the load inertia, smoothly controlling the motor start-up current from 5 to 7 times the rated value to within 2 times, achieving energy savings of 30-50% per start-up.

Intelligent braking management: Through energy feedback control algorithms, part of the kinetic energy during the braking process is converted into electrical energy and fed back to the power grid.

Load adaptive regulation: Real-time monitoring of the motor load rate, automatically reducing the supply voltage when the load is light to minimize iron loss and copper loss.

After a certain auto parts enterprise applied Godel intelligent motor control solid-state relays to its stamping production line, the annual power consumption of a single 200kW main motor dropped from 980,000 kilowatt-hours to 720,000 kilowatt-hours, achieving an energy-saving rate of 26.5%. The entire investment in the renovation was recovered within two years.

Innovation in Heating Systems:

Phase angle control power regulation: Achieves precise power adjustment within half a power frequency cycle, with control accuracy up to 0.5%, and avoids overshoot heating.

Multi-stage temperature curve: Set multi-stage heating, holding and cooling curves according to process requirements to reduce ineffective heating time.

Waste heat utilization control: intelligently maintain the base temperature during the heating off period to reduce the energy consumption of repeated heating by taking advantage of the thermal inertia of the system.

A certain chemical fiber enterprise in East China deployed Godelon power regulating solid-state relays in the spinning heating system, in combination with temperature closed-loop control. This enabled an overall energy efficiency improvement of 32% for the heating system, a reduction of 0.18 tons of standard coal per ton of product in unit energy consumption, and an annual saving of over 4,200 tons of standard coal.

System-level energy management: From single-point optimization to global optimization

Gordon uses solid-state relays as the end actuators of the industrial energy internet:

Real-time energy consumption monitoring: Integrated with high-precision current sensors, it can monitor the energy consumption data of each load circuit in real time.

Time-of-use electricity price response: Linked with the factory's energy management system, automatically reduce the operating power of non-critical loads during peak electricity price periods.

Dynamic power factor compensation: By optimizing the control strategy, the power factor on the load side is maintained above 0.95 to reduce reactive power loss.

Demand-side management: Participate in the power grid's demand response and orderly reduce load according to the preset strategy during periods of tight power supply.

In the "virtual power plant" pilot project carried out in a certain industrial park in Jiangsu Province, the 56 enterprises that were connected to the Godel Intelligent Energy Management System reduced their peak load by an average of 23% during the peak summer electricity consumption period. They received more than 8 million yuan in grid demand response subsidies and at the same time reduced the investment in backup capacity of diesel generators.

Full life cycle low-carbon design: A green closed loop from manufacturing to recycling

Gordon integrates green concepts throughout the entire product life cycle:

Low-carbon manufacturing process:

All production equipment is equipped with high-efficiency motors and variable frequency control, resulting in a 40% lower energy consumption per unit product compared to the industry average.

The application of water-based cleaning agents and low-temperature welding processes reduces the emission of volatile organic compounds.

A 5.2MW distributed photovoltaic system is installed on the factory roof, providing 5.2 million kWh of green electricity annually.

Innovations in Materials and Packaging:

Halogen-free flame retardant materials are adopted, and the products can be disposed of in an environmentally friendly way after scrapping.

The packaging materials are 100% recyclable, and the weight of packaging materials for each unit of product has been reduced by 35%.

Establish a product recycling system to professionally recycle precious metals and rare earth materials from decommissioned relays.

Extend service life:

With a design life of over 15 years, it is 3 to 5 times longer than traditional products, reducing the frequency of replacement and the generation of waste.

Modular design supports local replacement, avoiding the scrapping of the entire machine.

According to statistics, after using Godel solid state relays, customers have reduced the average amount of electronic waste generated during the product life cycle by 68%, and the carbon footprint throughout the entire life cycle has decreased by 42%.

Successful Practices of Empowering Green Transformation in Industries

Gordon solid state relays have demonstrated energy-saving potential in multiple high-energy-consuming industries:

Steel industry: The application in high blast furnace blower and steel rolling heating furnace control systems has achieved an average energy-saving rate of 18-25%.

Cement industry: Through the optimization control of the raw material mill and rotary kiln drive systems, a comprehensive energy saving of 15-20% has been achieved.

Textile industry: In the renovation of temperature control systems for setting machines and dyeing machines, energy-saving effects reach 22-30%.

Data center: With the intelligent control of precision air conditioning and UPS systems, the average PUE value is reduced by 0.05 to 0.08.

Taking a large cement group in Southwest China as an example, after comprehensively applying the Godel energy-saving solid-state relay and control system in the power drive systems of raw material mills and cement mills, the comprehensive power consumption per ton of cement dropped from 89 kWh to 76 kWh. The annual power savings exceeded 62 million kWh, reducing carbon dioxide emissions by 49,000 tons, which is equivalent to planting 2.7 million trees.

Green manufacturing is not only a social responsibility but also a strategic choice for enterprises to enhance their competitiveness. With solid-state relays as the core carrier, Godel Electric helps enterprises achieve visibility, controllability and optimization of energy consumption through technological innovation, transforming energy conservation and consumption reduction from a cost center to a value creation center. On the new track of carbon neutrality, Godel is willing to join hands with industrial enterprises to explore innovative paths for green development, using the power of technology to protect the green mountains and clear waters and create golden benefits.

Choosing Gorden is not only about choosing a product, but also about choosing a commitment to sustainable development for the future. Let's work together to create more value with less energy and contribute industrial strength to building a beautiful China.

推薦內容

25-12-26

25-12-25

25-12-19