Choosing the right solid-state relay is like finding a capable "general" for your system. However, to ensure this general performs effectively and stably in the long run, correct installation and usage are crucial. Many field failures are not due to product defects, but rather improper installation or overlooked details. Based on extensive field application experience, Gorden Electric Group has summarized the following key points and common pitfalls for you.Key Installation Points: Details Determine Success

Heat dissipation is the lifeline - must be taken seriously!

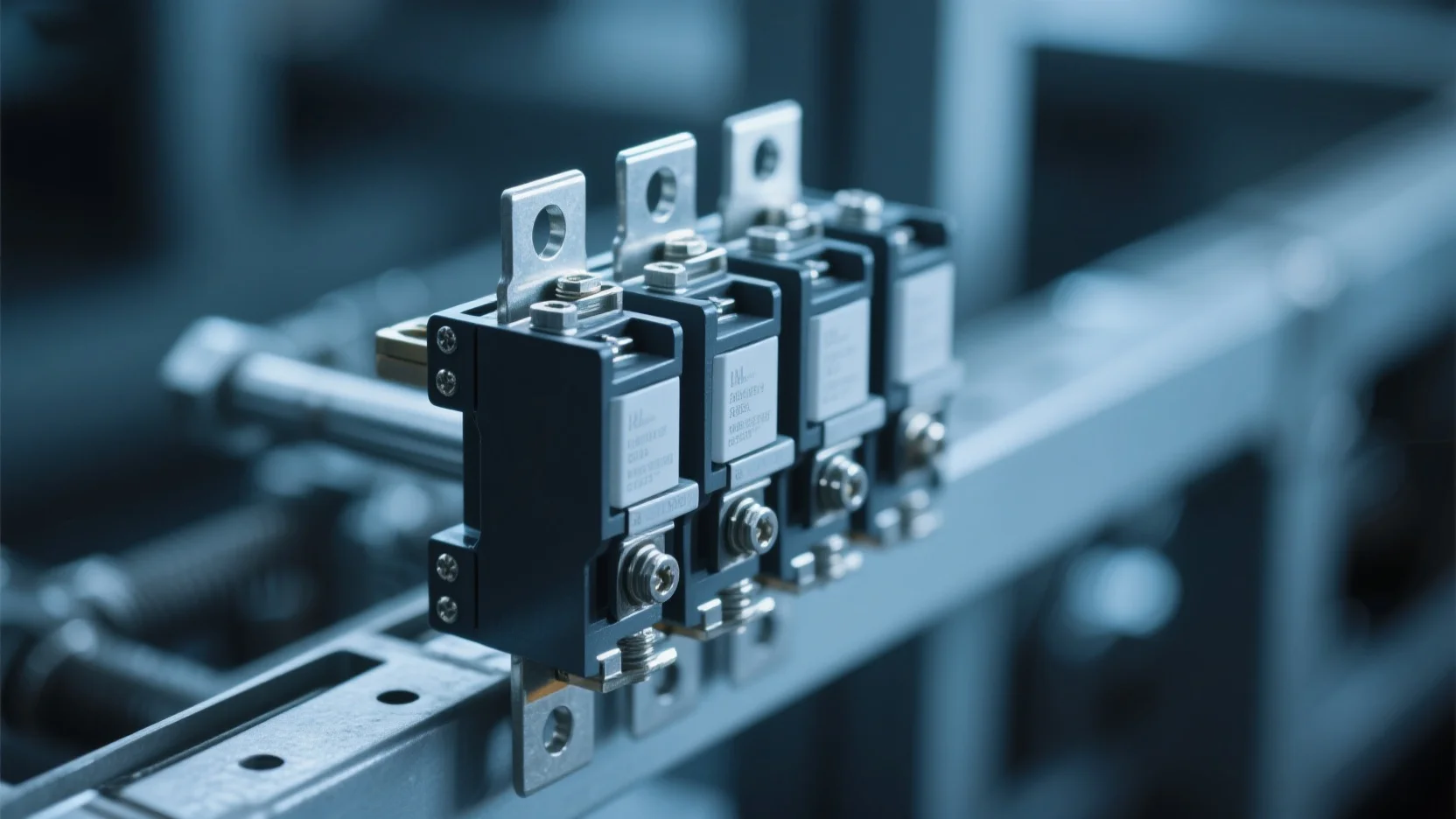

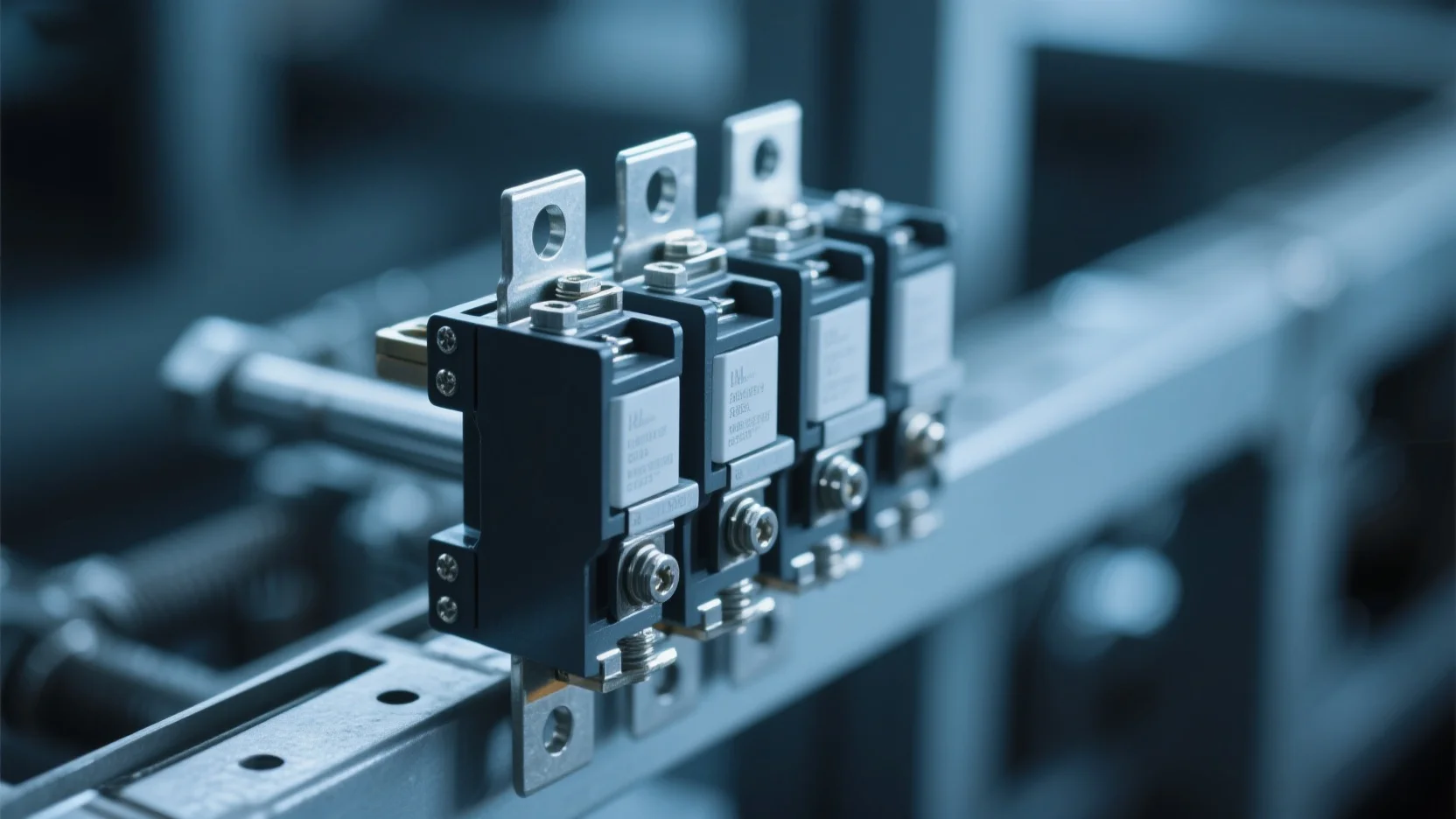

Installation Surface Treatment: Thermal grease must be applied between the solid-state relay and heat sink to fill microscopic gaps and reduce thermal resistance.Even Force Application: Mounting screws should be tightened gradually in a diagonal sequence to ensure even force distribution, maintaining tight contact between the solid-state relay base and heat sink.Heat Sink Selection: Choose a heat sink of sufficient size based on actual operating current and ambient temperature. When installing multiple solid-state relays side by side, appropriate spacing should be maintained, and airflow channel design should be considered to prevent heat accumulation.

Standardized Wiring is Essential— Guaranteeing Safety and Performance

Wire Gauge and Terminals

Use wire gauge that matches the working current

Ensure secure crimping of terminal connections

Prevent overheating due to excessive contact resistance

Keep Away from Heat Sources

Separation of Power and Signal Cables

Keep control signal wires (low voltage) separate from load power wires (high voltage)

Avoid parallel routing to minimize electromagnetic interference

If crossing is necessary, wires should cross at 90-degree angles

Protective Circuits are Essential - Preventive Fast-Acting Fuses: To protect solid-state relays from short-circuit damage, it is strongly recommended to series-connect fast-acting fuses in the load circuit. Conventional fuses are too slow to protect sensitive semiconductor devices. Varistors: In areas with significant power grid fluctuations or lightning strike risks, varistors should be connected in parallel at the output of solid-state relays to absorb surge voltages from the power grid.

Common Misconceptions and FAQs (Frequently Asked Questions)

Misconception 1: The resistance of a solid-state relay is zero after conduction?

Solution: Incorrect. Semiconductor devices have a forward voltage drop (typically 1.5-2V) when conducting, which results in conduction loss (P = voltage drop × current) that is converted into heat. This is why heat dissipation is necessary in high-current applications. It is not an ideal switch but rather a "lossy switch."

Misconception 2: Can solid-state relays completely replace electromagnetic relays?

Solution: Not really. Both have their own advantages and disadvantages. Solid-state relays excel in lifespan, speed, and shock resistance. However, electromagnetic relays still hold value in certain situations:

Multi-contact control: An electromagnetic relay can easily achieve simultaneous switching of multiple circuits, while solid-state relays are more costly in this regard.

Contact isolation: The contacts of electromagnetic relays are physically completely isolated when open, offering extremely high insulation resistance. This is still required in some special safety applications.

Low-cost, low-current applications: In simple, infrequently operated scenarios, electromagnetic relays maintain a cost advantage.

AC/DC versatility: Electromagnetic relay contacts can switch both AC and DC currents, while solid-state relays must be strictly distinguished.

Misconception 3: Why do solid-state relays still have a small leakage current after being disconnected?

Answer: This is a normal phenomenon. Due to the inherent characteristics of semiconductor devices, even in the off state, there will be a very small leakage current (usually at the mA level) flowing through. This may cause certain loads (such as LED lights) to remain slightly glowing when turned off. The solution is to parallel a suitable discharge resistor across the load.

How to determine if a solid-state relay is good or bad?

Preliminary judgment: When there is no input signal, the output resistance measured by a multimeter should be infinite; after applying the rated input signal, the output resistance should rapidly decrease to a lower value (with a conduction voltage drop). However, the most reliable method is to build an actual circuit with load for testing.

GOLDEN Electric's commitment to solid-state relays is a precision electronic product, and proper application is the stage for demonstrating its excellent performance. The GOLDEN Electric Group not only provides high-quality, multi-series solid-state relay products but also is committed to providing comprehensive technical support for customers, from selection to installation and maintenance. We believe that through scientific understanding and standardized operation, solid-state relays will undoubtedly inject stronger vitality and reliability into your equipment and systems, jointly promoting industrial control technology towards a smarter and more efficient future.